Say goodbye to stockouts and wastage, and hello to optimized materials management.

Transform your production planning and scheduling processes with Digicode’s advanced ERP software

Let’s investigate the most excellent fabricating ERP arrangements particularly outlined for little businesses. These specialized arrangements address the interesting needs and challenges confronted by small manufacturers, empowering them to compete successfully within the showcase whereas guaranteeing adaptability and feasible development.

When selecting the most excellent fabricating ERP for your little commerce, it’s imperative to consider key highlights that will optimize your operations and drive development. These highlights guarantee the consistent integration of all commerce capacities and empower effective decision-making.

Precise and real-time stock administration is significant for little fabricating businesses. Hunt for an ERP framework that gives comprehensive inventory tracking, real-time stock overhauls, and progressed request determining capabilities. This will assist you streamline your stock forms, diminish squander, and optimize your supply chain.

A strong ERP framework ought to give total perceivability into your supply chain, from obtainment to conveyance. It ought to empower you to track orders, screen provider execution, and oversee merchant connections viably. This include guarantees smooth coordination with providers and makes a difference recognize potential bottlenecks or delays.

An productive fabricating ERP ought to have generation planning capabilities that permit you to arrange and oversee your generation forms successfully. Seek for highlights such as computerized planning, generation determining, and capacity arranging to optimize asset allotment, minimize downtime, and maximize yield.

A top-notch manufacturing ERP system should include robust quality control features to maintain high product standards. Look for functionality that enables you to track and analyze quality metrics, set inspection criteria, manage non-conformance, and implement corrective actions. This will help you maintain consistency and meet customer expectations.

Monetary administration may be a critical perspective of any small business. Explore for an ERP framework that provides comprehensive money related modules, counting common record, accounts payable, accounts receivable, and budgetary announcing. This will assist you streamline financial forms, guarantee precise detailing, and make educated money related choices.

When it comes to finding the most excellent fabricating ERP frameworks for little businesses, a few best choices have demonstrated track records for conveying comprehensive functionalities, user-friendly interfacing, and versatility to back the development of little fabricating undertakings.

Let’s take a see at a few of the driving ERP arrangements within the advertise:

ERP Arrangement A could be a vigorous fabricating program that provides a wide extend of highlights custom fitted particularly for little businesses. It incorporates modules for stock control, generation arranging, quality administration, and financials. The user-friendly interface and adaptable customization alternatives make it an perfect choice for little producers.

ERP Arrangement B stands out as one of the finest ERP frameworks for fabricating. It underpins end-to-end fabricating forms, counting supply chain administration, shop floor control, and real-time analytics. Its instinctive interface and progressed announcing capabilities make it a beat choice for little producers.

ERP Arrangement C offers a comprehensive suite of highlights for little fabricating businesses. It incorporates modules for request arranging, materials administration, generation planning, and taken a toll bookkeeping. The cloud-based sending choice and consistent integration capabilities make it an amazing choice for little producers.

ERP Solution D is specifically designed for the manufacturing industry. It provides small businesses with tools for managing production, inventory, sales orders, and financials. Its scalability and flexibility make it suitable for growing manufacturing companies.

These top manufacturing ERP solutions offer small businesses the opportunity to optimize their operations, improve efficiency, and stay competitive in the industry. By carefully considering the specific needs of your business and evaluating the features and capabilities of each solution, you can choose the best manufacturing ERP system that aligns with your goals and drives success.

|

ERP Solution |

Key Features |

Deployment Options |

Scalability |

Cost |

|---|---|---|---|---|

|

ERP Solution A |

Inventory control, production planning, quality management, financials |

On-premises and cloud-based |

Scalable as per business requirements |

Affordable pricing plans |

|

ERP Solution B |

End-to-end manufacturing processes, supply chain management, real-time analytics |

Cloud-based |

Flexible scalability options |

Competitive pricing |

|

ERP Solution C |

Demand planning, materials management, production scheduling, cost accounting |

Cloud-based |

Easily scalable for business growth |

Cost-effective pricing plans |

|

ERP Solution D |

Production management, inventory control, sales orders, financials |

On-premises and cloud-based |

Highly scalable for expanding manufacturing businesses |

Varies based on features and customization |

When it comes to the leading ERP frameworks for fabricating, ERP Arrangement B stands out as a beat choice. This strong framework offers comprehensive back for end-to-end fabricating forms, making it an perfect arrangement for little producers.

One of the key qualities of ERP Arrangement B is its capacity to handle different perspectives of fabricating, counting supply chain administration, shop floor control, and real-time analytics. By coordination these functionalities, the framework guarantees consistent operations and enables producers with important experiences to drive educated decision-making.

The user-friendly interface of ERP Arrangement B improves ease of use and makes it simpler for little producers to explore the framework. Moreover, its progressed announcing capabilities give point by point perceivability into key fabricating measurements, empowering businesses to screen execution, recognize ranges for advancement, and optimize asset assignment.

With ERP Arrangement B, little producers can accomplish more prominent proficiency, efficiency, and dexterity in their operations. By streamlining forms, optimizing stock administration, and picking up real-time operational bits of knowledge, businesses can remain competitive within the energetic fabricating industry.

ERP Solution C is a comprehensive manufacturing software designed specifically for small businesses in the manufacturing industry. It offers a wide range of modules to streamline critical processes and enhance overall efficiency. With a focus on demand planning, materials management, production scheduling, and cost accounting, ERP Solution C provides the essential tools for optimizing operations and driving growth.

One of the key preferences of ERP Arrangement C is its cloud-based arrangement choice. This permits little producers to get to their ERP framework safely from anyplace, anytime, with real-time upgrades and consistent integration over offices. The cloud-based approach dispenses with the require for costly on-premises foundation and gives versatility for future development

Moreover, ERP Arrangement C offers instinctive interfacing and user-friendly route, making it simple for representatives to memorize and adjust to the framework. With its vigorous announcing capabilities, little producers can analyze basic information, pick up profitable experiences, and make educated choices to upgrade efficiency and productivity.

By and large, ERP Arrangement C is the perfect choice for little fabricating businesses looking for a comprehensive and adaptable computer program arrangement. Its cluster of highlights, cloud-based arrangement alternatives, and consistent integration capabilities make it one of the leading ERP computer program alternatives for optimizing fabricating operations.

When it comes to the best manufacturing ERP solutions for small businesses, ERP Solution D stands out as a top contender. Designed specifically for the manufacturing industry, this software provides small businesses with powerful tools to manage production, inventory, sales orders, and financials. With its scalability and flexibility, ERP Solution D is an ideal choice for growing manufacturing companies looking to streamline their operations and drive success in the industry.

When it comes to selecting the leading fabricating ERP framework for your little trade, cautious assessment is significant. Variables such as specific needs, budget contemplations, and future development plans ought to be taken into consideration. To guarantee a well-informed choice, it is suggested to assess the usefulness, adaptability, client back, and fetched of each ERP arrangement.

Assess whether the ERP computer program offers the particular highlights and modules that adjust along with your fabricating forms. Seek for capabilities such as stock control, generation arranging, supply chain administration, and monetary administration.

Consider the adaptability of the ERP framework. Can it suit the development of your trade and handle expanded exchange volumes as your operations grow?

|

ERP Solution |

Functionality |

Scalability |

Customer Support |

Cost |

|---|---|---|---|---|

|

ERP Solution A |

Comprehensive modules for inventory control, production planning, quality management, and financials |

Scalable to support growth and increased transaction volumes |

24/7 customer support with rapid response times |

Competitive pricing with flexible payment options |

|

ERP Solution B |

End-to-end support for supply chain management, shop floor control, and real-time analytics |

Easily adaptable to accommodate business growth |

A dedicated customer support team is available via phone, email, and live chat |

Transparent pricing structures with customizable packages |

|

ERP Solution C |

Robust functionality for demand planning, materials management, production scheduling, and cost accounting |

Scalable to meet the evolving needs of your business |

24/7 customer support with personalized assistance |

Affordable pricing models tailored to small manufacturing businesses |

|

ERP Solution D |

Comprehensive tools for managing production, inventory, sales orders, and financials |

Flexible scalability to accommodate business growth |

Responsive customer support is available during business hours |

Budget-friendly pricing options for small manufacturers |

This comparison table provides an overview of key features, scalability, customer support, and cost considerations for leading manufacturing ERP systems. It is essential to analyze your business requirements and align them with the strengths and capabilities of each ERP solution before making a final decision.

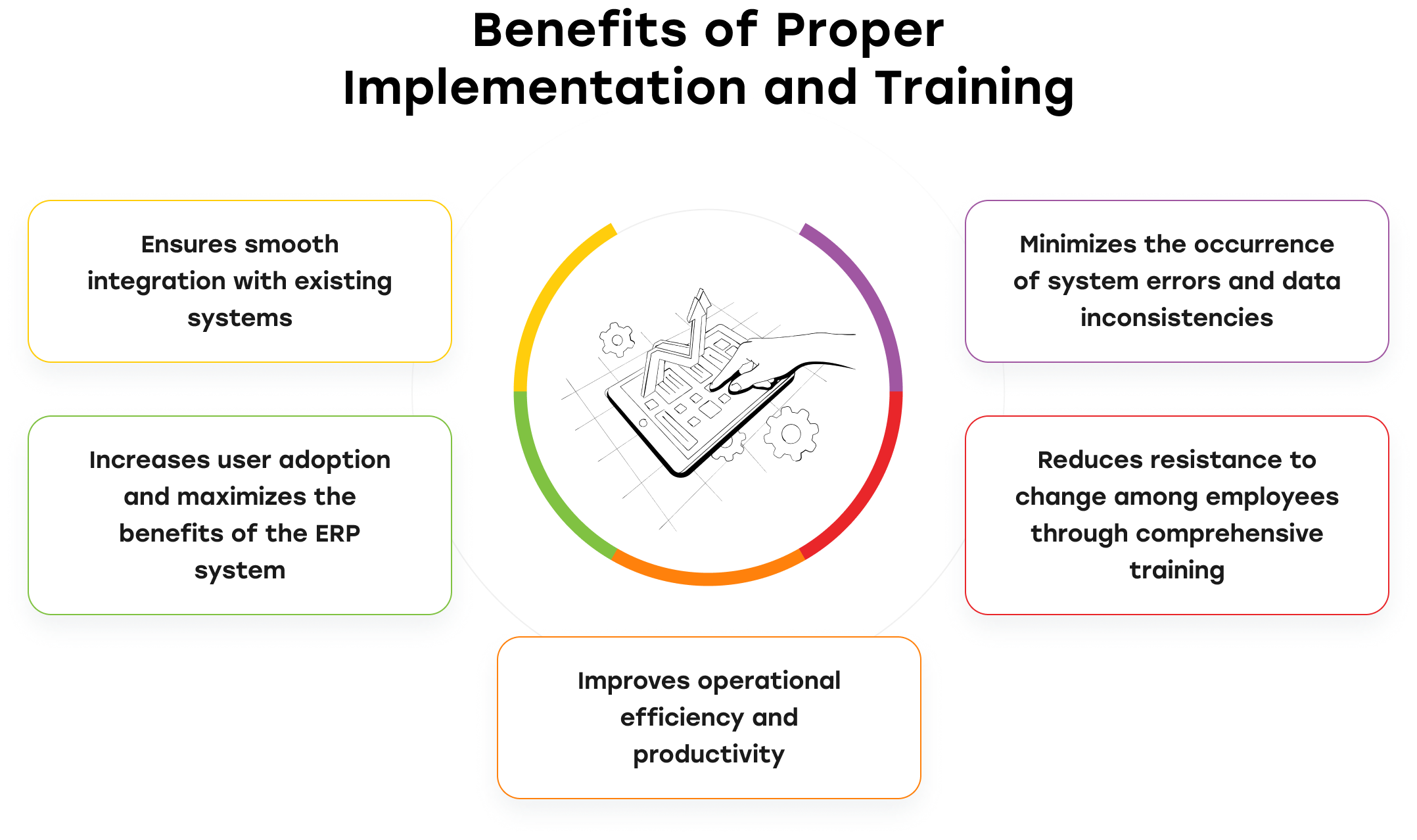

Once you’ve got chosen the most excellent fabricating ERP framework for your little trade, the another vital step is to guarantee its legitimate usage and give comprehensive preparing. This phase is fundamental to guarantee a smooth integration of the ERP framework together with your existing frameworks and to enable your workers to maximize the benefits it offers.

To realize a effective execution, it is prescribed to take after a organized approach that involves:

By contributing time and exertion in careful usage and preparing, you’ll be able set the establishment for a effective utilization of your chosen ERP framework in your fabricating operations.

Proper implementation and preparing are pivotal steps that ought to not be neglected when executing a fabricating ERP system. By guaranteeing a smooth integration and enabling your employees with the necessary information, you’ll open the total potential of your ERP framework and drive success in your fabricating trade.

Proper implementation and training are crucial steps that should not be overlooked when implementing a manufacturing ERP system. By ensuring a smooth integration and empowering your employees with the necessary knowledge, you can unlock the full potential of your ERP system and drive success in your manufacturing business.

Actualizing the most excellent fabricating program, too known as ERP (Endeavor Asset Arranging), can bring various benefits to small businesses within the fabricating industry. With the proper ERP framework in put, little producers can streamline their operations, make strides proficiency, and drive development. Here are a few key benefits of utilizing fabricating ERP:

In outline, the most excellent ERP program for fabricating gives little businesses with a comprehensive suite of highlights to streamline operations, improve efficiency, and drive development. By leveraging fabricating ERP, small manufacturers can pick up a competitive edge within the showcase and position themselves for long-term victory.

Investing in the best ERP system is a big step for small businesses. By leveraging the right technology, small manufacturers can optimize their operations, drive growth, and stay ahead of the competition.

Digicode specializes in offering small manufacturing businesses customized ERP solutions designed to enhance operational efficiency and drive growth. Leveraging our expertise in technology consulting and system integration, we collaborate closely with clients to understand their specific requirements and challenges. Our team then tailors ERP systems to streamline critical processes such as inventory management, production planning, and financial control, ensuring a seamless integration with existing workflows. With Digicode’s ongoing support and training initiatives, small manufacturers can confidently adopt and optimize their ERP solutions, leading to improved productivity, cost savings, and overall operational excellence.

Key features to consider include inventory management, production planning, resource allocation, financial management, and communication tools.

How can a manufacturing ERP system help optimize production scheduling and resource allocation?

By providing real-time visibility into production processes and resource availability, ERP systems enable efficient scheduling, allocation, and monitoring of production tasks.

What role does inventory management play in the success of small manufacturing businesses, and how does an ERP system facilitate it?

Effective inventory management is crucial for minimizing stockouts and waste. ERP systems track inventory levels, streamline procurement processes, and provide insights into inventory turnover rates.

Can a manufacturing ERP system provide insights into financial performance and help identify areas for cost savings?

Yes, ERP systems offer comprehensive financial management capabilities, including cost accounting, budgeting, and expense tracking. These insights help identify cost-saving opportunities and improve financial decision-making.

How does collaboration and communication improve within an organization through the implementation of a manufacturing ERP system?

ERP systems centralize data, making information accessible to all departments. This enhances collaboration by enabling seamless communication and coordination between production, inventory management, purchasing, and sales teams.

Related Articles